- response@ointmentandsyrupplant.com

- 9833865058 / 8879192449

Buy The Highest Quality Liquid Manufacturing Plant on Bipin Pharma

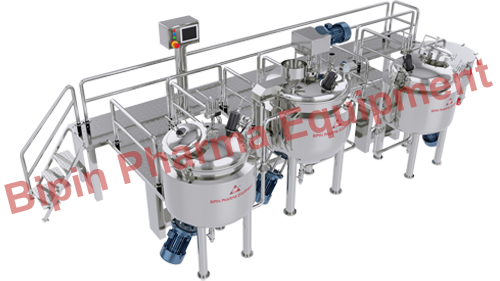

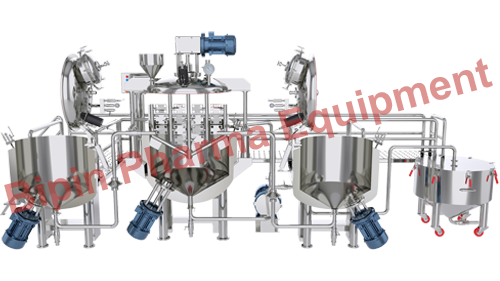

Production of oral liquids/syrups in the pharmaceutical industry is a complex process that demands a well-designed liquid manufacturing plant. We, here at Bipin Pharma Equipment, understand this and have devised exceptional oral drop & liquid manufacturing plant at an affordable value. Our innovative portfolio of pharmaceutical products combine innovative technology with superior quality materials to offer effective results every time.

The liquid manufacturing plant is available in diverse capacities, ranging from 500 to 1000 liters. These plants are capable of managing to vital aspects of oral/liquid product in pharmaceutical industry: minimal manpower handling and 100% cleanliness during the process of manufacturing. They contain various segments including sugar syrup vessel, sugar syrup pre-filter, manufacturing vessel, storage vessel, inline homogenizer tank, control panel and a product piping system.

Manufacture and Design of Liquid Manufacturing Plant

What are the specifications?

• Outer Body Made of Stainless Steel (SS)

• Vessels Abide by CGMP Construction (Paint-Free)

• Door Gaskets Created From Food-Grade Silicon

• Contact Parts Made of SS 304 And Class 4B Mirror Finish

How is the design?

• The outer and inner body of the plant is created from the highest grade of stainless steel.

• The various pipes/ pipe fittings along with valves are made from SS 304 / SS 316 having tri-clover joints.

• The vessels can handle a pressure of over 1 kg per square meter, as a result of which they can be sterilized.

What are the features?

• Microprocessor based automatic operation, enabling users to operate the plant as per their own set of requirements.

• Closed circuit manufacturing, right from the feeding of sugar to the loading of the volumetric machine.

• Sugar Syrup vessel holds a electrical heater and high-speed stirrer for effective emulsion of liquids.

• Prepared syrup gets transported from the sugar syrup vessel to manufacturing vessel via a vacuum pump.

• Recirculation of liquid occurs through the liquid transfer pump, and this pump discharges the final product to the storage vessel.

• Storage vessel is moved to filling segment and gets connected to a pump that would transfer the product to a filling machine.

• All the inter-connecting pipes part of the plant are electro-polished inside.

• Easy to use work platform is equipped for the operation and maintenance of the liquid manufacturing plant.

What are the optional accessories?

• Customized Control Automation

• In-Line Emulsifier For Superfast Emulsion

• SIP & CIP Connections

Applications

A Liquid Manufacturing Plant is a facility where various types of liquid products are produced and packaged. These plants are often equipped with tanks, mixers, fillers, and other specialized machinery to handle the production, processing, and packaging of liquid goods. Here are some of the primary application areas :

- Industry

- These plants manufacture a range of liquid pharmaceuticals including syrups, suspensions, injectable solutions, and oral liquid medications.

- Food and Beverage Industry

- In this sector, they are used for the production of various liquid products such as soft drinks, juices, sauces, dairy products, and more.

- Chemical Industry

- Liquid manufacturing plants in the chemical industry may produce a wide range of products, from industrial solvents to household cleaning products.

- Cosmetics Industry

- These facilities produce liquid cosmetics like creams, lotions, liquid soaps, shampoos, conditioners, and other skin care and personal hygiene products.

- Oil and Gas Industry

- In this industry, liquid manufacturing plants can refer to refineries and facilities where crude oil is processed and refined into usable products like gasoline, diesel, and heating oil.

- Paint Industry

- These plants are used for the production of different types of paints, coatings, and related products.

- Detergent Industry

- Liquid manufacturing plants produce liquid detergents, fabric softeners, dishwashing liquids, and other related products.

- Breweries & Distilleries

- These plants produce alcoholic beverages like beer, wine, whiskey, etc.

In essence, any industry that requires the mass production of liquid products will utilize a liquid manufacturing plant.